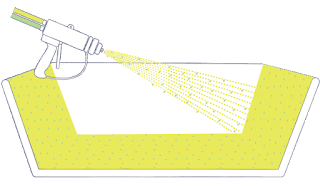

Composite by Spray-Up Process

Spray-Up Process

As with hand lay-up, gel

coat is first applied to the mold prior to spray-up of the substrate laminate.

Continuous strand glass roving and begin resin are fed through a chopper gun,

which deposits the resin-saturated "chop" on the mold. The laminate

is then rolled to thoroughly saturate the glass strands and compact the chop.

Additional layers of chop laminate are added as required for thickness. Roll

stock reinforcements, such as woven roving or knitted fabrics, can be used in

conjunction with the chopped laminates. Core materials of the same variety as

used in hand lay-up are easily incorporated.

Spray-up also known as chopping, is an open mold method similar to hand lay-up in its Used for making boats, tanks, transportation components, & tub/shower units in a large shapes and sizes. A chopped laminate has good conformability so, sometimes faster to produce than a part made with hand lay-up when molding complex shapes.

In the spray-up process the operator controls thickness and consistency, therefore the process is more operator dependent than hand lay-up. Although production volume per mold is low, it is feasible to produce substantial production quantities using multiple molds

Comments

Post a Comment