Composite by Filament Winding

Filament Winding

The process makes the high strength-to-weight ratio laminates and provides a high degree of control over uniformity and fiber orientation. The filament winding process can be used to make structures which are highly engineered and meet strict tolerances. Because filament winding is automated, the labor factor for filament winding is lower than other open molding processes.

Process

Continuous

strand roving is fed through a resin bath and wound onto a rotating mandrel.

The roving feed runs on a trolley that traverses the length of the mandrel. The

filament is laid down in a predetermined geometric pattern to provide maximum

strength in the directions required. When sufficient layers have been applied,

the laminate is cured on the mandrel. The molded part is then stripped from the

mandrel. Equipment is available for filament winding on a continuous basis and

two axis winding for pressure cylinders

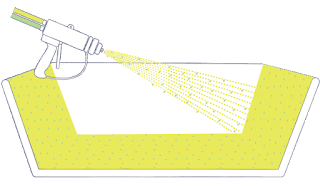

*Filament

winding can be combined with the chopping process and is known as the hoop chop

process.

Molds

Filament winding uses mandrels of suitable size and shape, made of steel or aluminum, to form the inner surface of the hollow part

⇐ Spray-Up Process

⇐ Spray-Up Process

Comments

Post a Comment