Composite by Hand Lay-up Process

What are composites ?

A composite is a material made from two or more different materials with different physical or chemical properties that, when combined, are stronger than those individual materials by themselves

composites are used from ancient period of time like bricks, mud, straw, etc.

Now question is arise that how to make composite, what was its methods or process???

The process which is use for making composites are known as molding, These are of three types:-

The process which is use for making composites are known as molding, These are of three types:-Open Molding

Closed Molding

Cast Polymers Molding

Each process have there own benefits

Now,We can study go through Each process in this blog we'll study about Hand Lay-up process which is a part of open molding:

Open Molding

In open molding process, Raw material like Resins and Fiber Reinforcement are exposed in air for cure and harden. It go through by different of process like Hand Lay-up, Spray-Up, Casting and Filament Winding

Hand Lay-up Process

Hand lay-up is an open molding method suitable for making

a wide variety of composites products from very small to very large. Hand lay-up is the most common and least

expensive open-molding method because it requires the least amount of

equipment. In this method Fiber reinforcements are placed by hand in a mold

after that resin is applied with the help of brush or roller. it is feasible to

produce substantial production quantities using multiple molds.

Hand lay-up is the simplest composites molding method,

offering low cost tooling, simple processing, and a wide range of part sizes.

There is a minimum investment in equipment. And they give good production rates

and consistent quality is obtainable.

This process is used to make both large and small items,

including boats, storage tanks, tubs and showers.

Process

Firstly

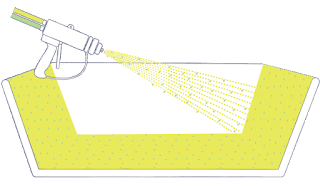

we applied Gel coat with the help of spray gun for better quality surface. When

the gel coat has applied properly, roll stock fiberglass reinforcement is

manually placed on the mold. The laminating resin is applied by brushing, spray

or paint roller. Paint rollers are used to consolidate the laminate, thoroughly

wetting the reinforcement and removing entrapped air. Different layers of fiberglass reinforcement are added

to build laminate thickness. Low density core materials used to stiffen the laminate.

Molds:

Simple, Single cavity molds of fiberglass composites construction are generally used. or low cost mold used.

Spray-Up Process ⇨

Spray-Up Process ⇨

Comments

Post a Comment