Composite by Filament Winding

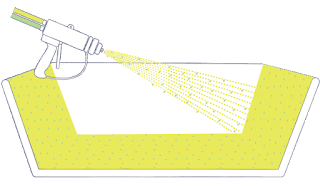

Filament Winding Filament winding is an automated open molding process that uses a rotating mandrel as the mold. The male mold configuration produces a finished inner surface and a laminate surface on the outside diameter of the product. Filament winding results in a high degree of fiber loading, which provides high tensile strengths in the manufacture of hollow, generally cylindrical products such as chemical and fuel storage tanks, pipes, stacks, pressure vessels, and rocket motor cases. The process makes the high strength-to-weight ratio laminates and provides a high degree of control over uniformity and fiber orientation. The filament winding process can be used to make structures which are highly engineered and meet strict tolerances. Because filament winding is automated, the labor factor for filament winding is lower than other open molding processes. Process Continuous strand roving is fed through a resin bath and wound onto a rotating mandrel. The ro...